- USE CLICK PLC AS MODBUS SERVER MOVIE

- USE CLICK PLC AS MODBUS SERVER SERIAL

- USE CLICK PLC AS MODBUS SERVER SOFTWARE

- USE CLICK PLC AS MODBUS SERVER FREE

The panel can be assembled with all relevant devices to provide/control of the power being supplied to each individual lighting circuit. I agree with the other poster.īack to electrical panels with integrated PLC unit. Real PLCs are robust and can take a lot of abuse so to speak. They are nice but they are not for industrial application. I built it with six speakers with built-in tweeters.

USE CLICK PLC AS MODBUS SERVER MOVIE

The thundering effect of the sound track makes for a movie house effect. I had a good run with it with the kids when I used it for the AVATAR movie when it first came out. I built my Home Theater Surround Sound from a Velleman Kit. “REAL” PLC.Īrduino kits and Velleman of Germany have all kinds of components that will make hobbyists and DIYs happy. It’s amazing how many electronic products on the market -that you will find almost as a good as those you mentioned. Don't saddle your client with an unreliable and unmaintainable system when a better alternative exists. Honestly, it's probably cheaper to use a PLC, once you factor all the time and other crap you need to make a Pi control anything. You can get a proper PLC (with Ethernet) for not much more than a Pi. To suggest otherwise is a potential hazard. They certainly serve a purpose, but that purpose is not industrial controls.

Inspectors may not like them either, but probably because they don't understand them. They're not Listed or Recognized components, and without jumping through a bunch of hoops, a panel built with one is unlikely to pass a UL inspection. Who are they supposed to call for Ras Pi tech support, other than the person who wrote the program?Īnd that's just the hardware. If they have questions, they can call the PLC manufacturer for tech support. If they have no way to support it, they'll rip it out, and curse your name for supplying something they can't maintain. Ladder logic is pretty easy to understand for most electricians Python (or another "computer" language) is not. Good luck finding a Pi 3B+ ten years from now, along with the particular distro of Linux you'll need to run that bespoke program you wrote for lighting control. And, you can get a replacement in ten years, if one does suffer a failure (lightning strike, etc.). They also usually don't care how or if they're unceremoniously power cycled. PLC's are designed to run for decades and they do all the time. The cost of proper hardware is small in comparison to downtime and damaged customer relations due to crashed hobbyist-grade hardware. You can't directly control a contactor coil with 3.3V I/O, which means you're now cobbling together even more not-meant-for-industrial-controls hardware, shields, etc. Their I/O isn't hardened, and can't directly control anything larger than a blinky LED. If a Pi runs without issue for more than a year or two, it's rare. The only way to recover from that is to wipe the card and reload, hopefully from a backup (you did make a backup, right?). They have a disturbing tendency corrupt their SD card if not properly powered down, or for no real reason at all. It works well for the most part, but I absolutely would not use a Pi in an industrial controls application. I have one on my home network doing ad blocking. They're meant to be used to teach the basics of Linux and programming. A Raspberry Pi is not a device meant to control anything in an industrial control panel.

USE CLICK PLC AS MODBUS SERVER FREE

I know you can handle it- if not feel free to consult a Network Engineer. It makes it easier to grasp the vagaries of the science of networking. I have to admit- needs an understanding of the OSI network architecture. Programming the PLC and integrating them into the panoply of protocols, hardware and software. Some call it HMI (human-machine-interface)

USE CLICK PLC AS MODBUS SERVER SOFTWARE

This is when you need to integrate SCADA (supervisory control and data acquisition) software and peripherals so you can monitor and operate those lights thru automatic command from the PLC and also be able to override the auto functions in case your PLC craps out. Seriously, you would want to make sure that those lights (the controlled ones) come on as programmed and off when they should be.

You'd be bored watching those LEDs blinking in sequence indefinitely. Since the operation becomes "fixed" on the PLC end-the PLC doesn't need to be monitored. The PLC would drive those relays/contactors to control those lights.

USE CLICK PLC AS MODBUS SERVER SERIAL

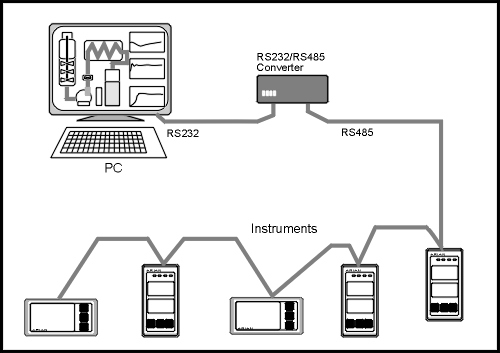

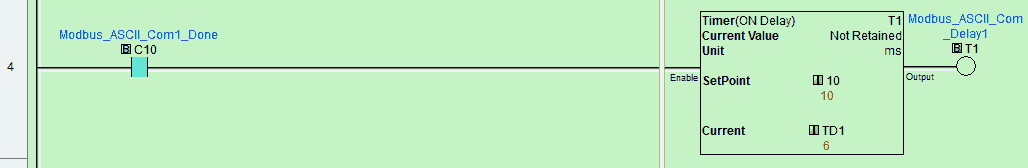

You program your PLC from your PC or lap top and upload it to your PLC MODBUS unit via RS- 485 serial cord. Just make sure that you get the Modbus-enabled PLC unit with an RS-485 port and network adapter to plug into your vacant ethernet switch. Sure you can integrate your PLC lighting control using the Modbus Network.

0 kommentar(er)

0 kommentar(er)